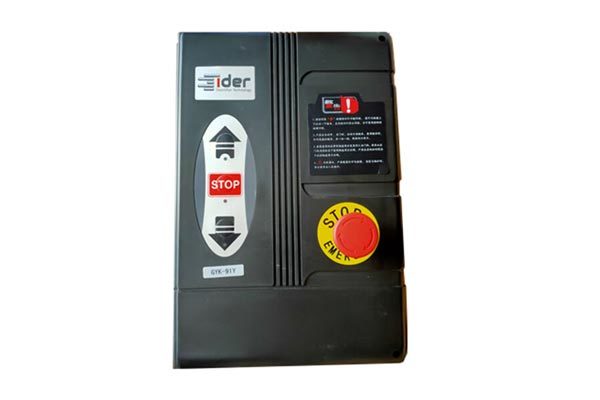

control box

Category:

Accessories

Keywords:

Accessories

Production Process

Each controller is strictly quality controlled before leaving the factory. When unpacking, please carefully confirm whether there is any damage or scratches during transportation, and whether the rated value on the nameplate of the machine is consistent with your order requirements.

C series technical parameters

|

model |

dw5 |

dw5-1 |

|

|

|

box material |

abs plastic |

|

||

|

Size (length, width and height) |

303*123*142 |

300*190*144 |

mm |

|

|

installation method |

vertical installation, no vibration |

|

||

|

Input power supply voltage |

Single-phase AC200-240 |

v |

||

|

Enter power supply frequency |

50/60 |

hz |

||

|

maximum output power |

1.5 |

kw |

||

|

power supply capacity to external equipment |

12 |

VDC |

||

|

0.4 |

a |

|||

|

Work temperature |

-20 ~+50 |

℃ |

||

|

Storage temperature |

-20 ~+55 |

℃ |

||

|

Environmental humidity |

30%-85%, no dew |

|

||

|

Place of use |

indoor, not directly exposed to sunlight, dust -free, corrosive gas, oil fog, water vapor, etc. |

|||

|

weight (net weight) |

1.0 |

kg |

||

A series technical parameters

|

model |

PE215 |

PE515 |

PE715 |

PE915 |

|

|

|

output power |

0.75 |

1.5 |

2.2 |

3.8 |

kw |

|

|

box material |

Cold -rolled steel plate |

|

||||

|

Size (length, width and height) |

450*250*180 |

490*255*181 |

mm |

|||

|

Installation method |

vertical installation, no vibration |

|

||||

|

Input power supply voltage |

Single-phase AC200-240 |

v |

||||

|

input current |

6.5 |

13 |

18 |

32 |

a |

|

|

Input power frequency |

50/60 |

hz |

||||

|

power supply capacity to external equipment |

24 |

VDC |

||||

|

0.4 |

a |

|||||

|

Work temperature |

-20 ~+50 |

℃ |

||||

|

Storage temperature |

-20 ~+55 |

℃ |

||||

|

Environmental humidity |

30%-85%, no dew |

|

||||

|

Place of use |

indoors, not directly exposed to sunlight, dust -free, corrosive gas, oil fog, water vapor, etc. |

|||||

Installation precautions:

The motor and controller must be grounded. When installing, debugging and opening and closing the door, it is strictly forbidden to stand or walk under the door; when installing the motor unit, the door shaft needs to be inserted more than half of the reducer. Before closing the door curtain, check whether there is an obstacle under the door curtain. If there is, it must be cleaned.

Equipment

The company has advanced equipment: 6-meter optical fiber cutting machine, 6-meter large bending machine, automatic slitting shearing machine, robot welding, hard shutter board fully automatic assembly line, automatic cloth cutting machine, continuous heat sealing machine, aluminum profile extrusion machine, fully automatic spraying assembly line, etc.

RELATED PRODUCTS